Architectural Class I Anodize

Class I anodize is used on the exterior of architectural projects. It has a higher mil thickness than Class II anodize; it is more resistant to salt spray and the sea coast; and it is more durable in high traffic areas.

Class I anodize, with a minimum mill thickness of 0.7 (18 microns), can be a suitable choice for coastal climates as it possesses exceptional resistance to corrosion, discoloration and wear; however, its natural beauty can be marred by harsh chemicals, rough conditions or neglect. These conditions may only affect the surface finish and not reduce the service life of the aluminum, but mortar, cement, and other alkaline materials will quickly corrode an anodize finish if allowed to dry on the metal surface.

Class I anodize meets or exceeds all requirement of AAMA 611 “Voluntary Specification for Anodized Architectural Aluminum

STRENGTHS & LIMITATIONS

The performance strengths and limitations of paint are summarized as follows:

Strengths of Anodize

• Color stability

• Hardness, compared to a sapphire

• Durability, abrasion resistance

• Anodize protects and maintains the structural integrity of the aluminum

• Non-hazardous, produces no harmful or dangerous by-products

• Ease of maintenance

Limitations of Anodize

• Limited color choices

• Difficult touch up

• Color may vary depending on alloy & trace elements in aluminum

• Surface imperfections of the aluminum may show through the anodize

Anodize touch-up should not be needed in most cases because anodizing is so hard that it is not easily scratched. Touch-up paint should be used extremely sparingly over anodize. Only the visible raw aluminum in the scratch or gouge should be touched up with matching paint (Alodine pretreatment should be applied first). In most cases, the match will not be ideal as anodizing is a transparent to translucent coating while paint typically is opaque and will not blend in.

Other fixes include:

Replacing the damaged piece with a new one

Cladding the damaged piece with another anodized piece

Clean, pretreat and paint the entire assembly.

None of these “other fixes” are good ones. The best repair is not to allow the material to get damaged in the first place. The number one cause of damage on the jobsite is not protecting the anodized material from harsh chemicals such as concrete/mortar or muriatic acid/brick wash. If reasonable care is taken during handling and high and low pH chemicals can be avoided, repair and/or touch-up of an anodize finish will not be needed.

What is Kynar®?

Kynar 500® is not a finished paint. It is a trade name for PVDF (polyvinylidene fluoride) resin, as is Hylar 5000®.

PVDF resin is the raw material used by licensed formulators to manufacture PVDF based coatings. When formulated into a coating composition, the paint contains a minimum of 70% by weight of Kynar 500® resin to manufacture a 70% Kynar 500® resin based coating, that meets the highest performance criteria of AAMA – 2605.

The key to a products performance is the resin chemistry. For the ultimate long-term durability, time has shown that PVDF resin is the one to choose. Other coating resins include acrylic, polyester, silicone polyester and urethane.

Vale offers all kynar® finishing options for aluminum framing and door trim. Two or three coat options are available in addition to custom color matching for all your painting requirements.

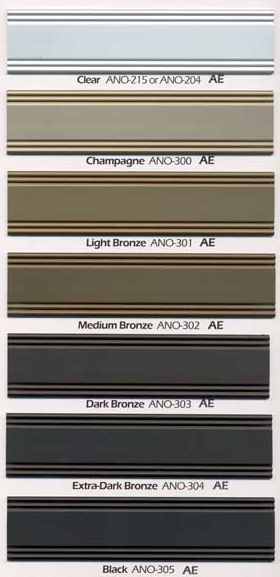

Anodized Color Chart

CLEANING ANODIZED MATERIAL AAMA 609 / 610 cleaning and maintenance guide for architectural finished aluminum

Anodized material has an extremely hard surface that is very colorfast and mar resistant. The Class I clear or color anodized finishes applied by a computer automated, high quality commercial anodizer specializing in architectural finishing will provide consistent color and long product life in a variety of applications.

Much like painted surfaces, an anodized finish should be cleaned using mild soap solutions to retain its original beauty. Products that are safe for use with bare hands including most commercial cleaning products can be safely used. The cleaning solution should be applied with a soft cloth, sponge or brush. Avoid the use of strong acid or alkali cleaners.

Severely soiled anodized surfaces can be cleaned a little more aggressively than painted surfaces. For example, slight scuffmarks and rub marks on an anodized surface can be removed with a mild abrasive pad such as the Scotch-Brite pad. Use the pad to remove the mark, and then clean the surface using the mild soap solution. Rinse the surface thoroughly with clean water and dry with a soft cloth.

As with painted surfaces, in coastal areas where the finish is exposed to salt spray or in areas containing heavy industrial pollutants the cleaning should take place on a regular maintenance program.

FIELD TOUCH UP